Latest News:

"Recently, ALKEL120, a hydrogen production unit developed by Ally, was successfully shipped overseas,

injecting new vitality into the global hydrogen energy sector."

This success is the result of extensive collaboration and coordination.

Chengdu Ally New Energy Co., Ltd.

Ally New Energy was responsible for the research and design of this unit. With a professional team and extensive design experience, they successfully integrated customer needs with actual manufacturing in areas such as electrolyzer structure, catalyst selection, and process optimization. The overall design showcased outstanding technical prowess.

Ally New Energy is committed to combining innovation with practicality, providing the best technical solutions for every project, and striving to meet and exceed customer expectations as both designers and problem solvers.

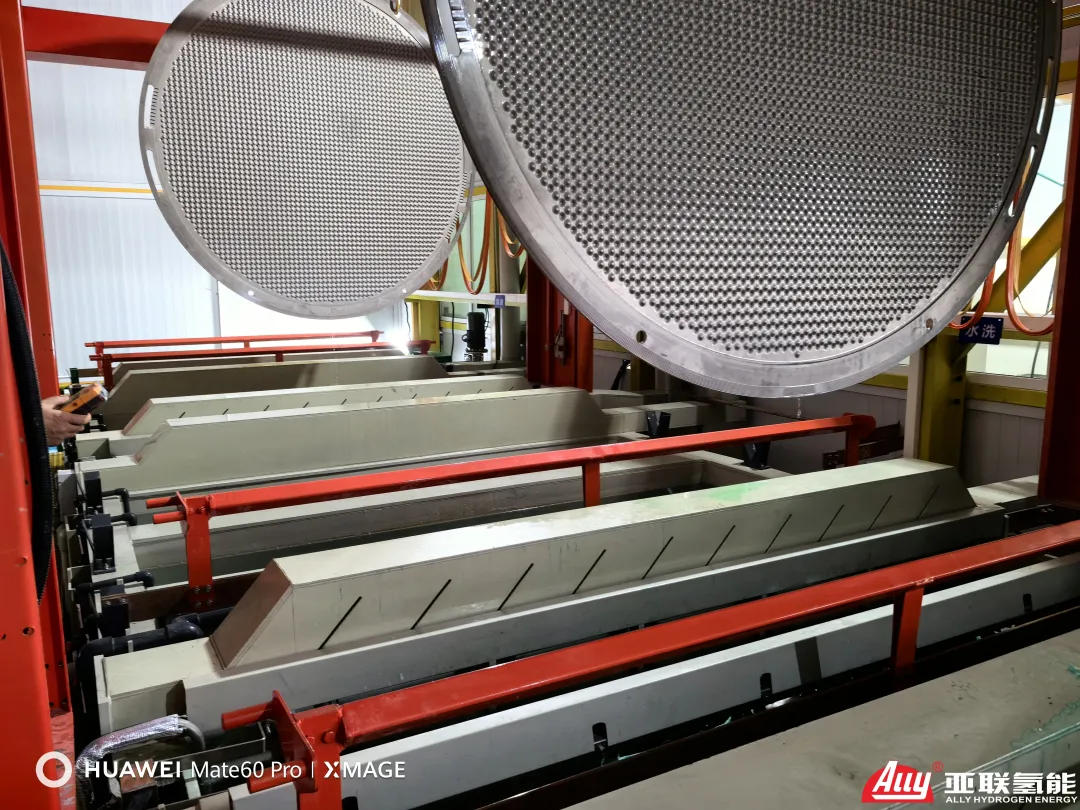

Tianjin Ally Hydroqueens Energy Co., Ltd.

Ally Hydroqueens Energy undertook the machining and assembly of the electrolyzer. By fully utilizing core technologies, they ensured that every component met the highest standards, laying a solid foundation for the precise and reliable manufacturing of the unit.

Ally Hydroqueens Energy, occupying 5,500 square meters, leverages Ally Hydrogen Energy's technical expertise, focusing on electrolyzers to achieve full-chain production of electrolyzer equipment, with an annual capacity of 150 sets of water electrolyzers ranging from 50 to 1,500 standard cubic meters, with a total capacity of 1 GW.

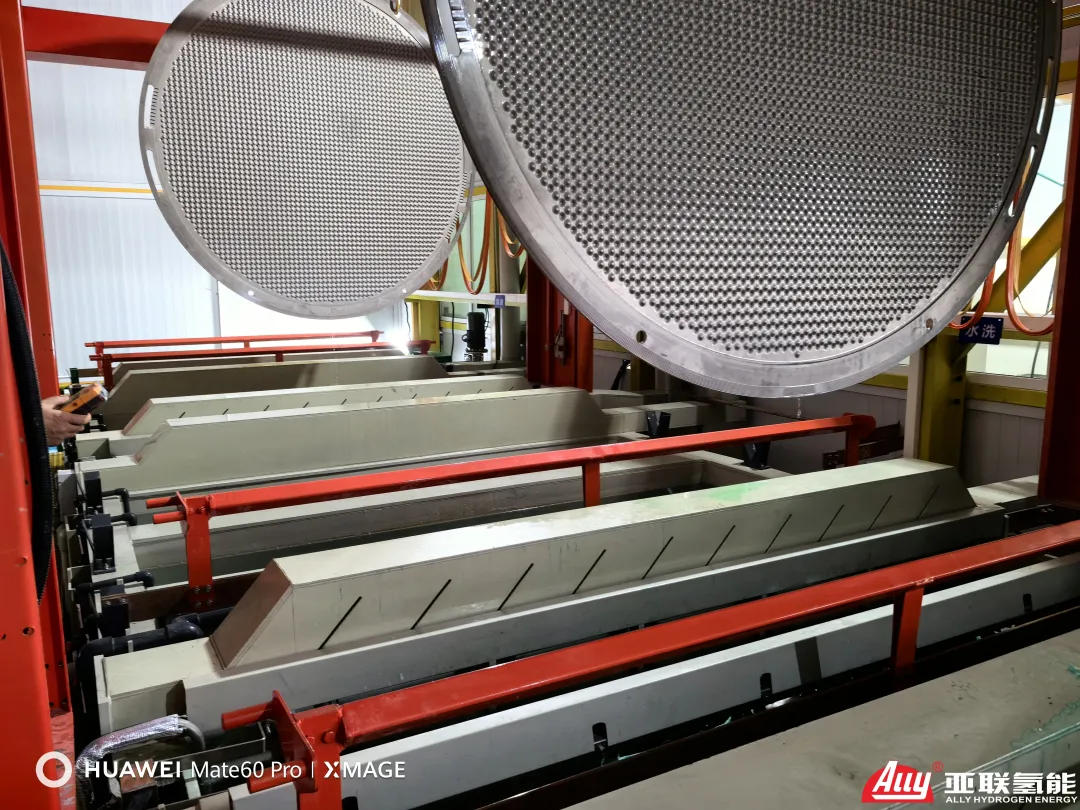

Sichuan Liancai Metal Surface Treatment Co., Ltd.

Sichuan Liancai Metal Surface Treatment Co., Ltd. was responsible for electrode plating and provided electrodes, enhancing metal corrosion resistance and extending service life through advanced production processes. Quality was ensured through methods such as blue point testing, thickness testing, and adhesion testing, guaranteeing the quality of the electrolyzer plates and ensuring the unit's efficient operation and long-term stability.

As a specialized electroplating company, Sichuan Liancai has provided electroplating processing for electrolyzer plates to many well-known domestic and international companies. Its advanced electroplating technology and quality inspection standards have been widely recognized in the industry, truly safeguarding the stable hydrogen production of alkaline electrolyzers.

Chengdu Ally High-Tech Machinery Co., Ltd.

Ally High-Tech Machinery was responsible for the skid-mounted installation and commissioning of the unit, including the integration and installation of the electrolyzer, gas-liquid separation system, purification system, power system, and control system.

The entire team ensured the overall performance and stability of the unit with their exquisite skills and meticulous attitude, providing strong support for the smooth progress of the entire project.

Sichuan Kaiya Hydrogen Energy Equipment Technology Co., Ltd.

Finally, it is worth mentioning that the comprehensive testing on Kaiya Hydrogen Energy's professional testing platform ensured that all data met the expected standards, aligning with international standards and customer quality requirements.

This testing platform has tested electrolyzers for well-known domestic central enterprises and has been recognized by domestic professional standards institutions.

Kaiya Hydrogen Energy, which is currently under construction, aims to become a full-chain super factory integrating research and design with manufacturing, setting benchmarks in hydrogen production equipment manufacturing and testing.

Ultimately, through the above-mentioned collaboration and effort, the entire unit successfully obtained CE certification. This certification indicates that the unit complies with relevant European regulations and standards, opening the door to the international market and demonstrating Ally Hydrogen Energy's high level of expertise and strong capabilities in the hydrogen production equipment manufacturing field as a "Chinese hydrogen energy expert."

research and development results

research and development results